Chemical burns, blindness and scrapes are just a few the hazards workers face while not

using PPE on the job. Despite these grave risks, 85% of industrial workers in a

recent Kimberly-Clark Professional survey said they had observed others failing

to wear eye protection when they should have been. "The results are very

disconcerting when you consider that 90% of eye injuries can be

prevented through the use of proper protective eyewear,” says Valona

Renner-Thomas, Product Manager at Kimberly-Clark Professional. What is ironic

is that eyewear came in first when respondents were asked to rank the most

important PPE category for on-the-job safety. It was also deemed the “most

challenging" PPE category in terms of compliance. When asked what would most improve compliance

with eye protection protocols, the top choice was more comfortable eyewear

(56%) followed by fog-free lenses (22%). These alarming statistics should raise

a red flag for employers. Increased workers’ compensation costs and injuries

can result from even a slight eye injury. For more information on eye

protection, click here.

Chemical burns, blindness and scrapes are just a few the hazards workers face while not

using PPE on the job. Despite these grave risks, 85% of industrial workers in a

recent Kimberly-Clark Professional survey said they had observed others failing

to wear eye protection when they should have been. "The results are very

disconcerting when you consider that 90% of eye injuries can be

prevented through the use of proper protective eyewear,” says Valona

Renner-Thomas, Product Manager at Kimberly-Clark Professional. What is ironic

is that eyewear came in first when respondents were asked to rank the most

important PPE category for on-the-job safety. It was also deemed the “most

challenging" PPE category in terms of compliance. When asked what would most improve compliance

with eye protection protocols, the top choice was more comfortable eyewear

(56%) followed by fog-free lenses (22%). These alarming statistics should raise

a red flag for employers. Increased workers’ compensation costs and injuries

can result from even a slight eye injury. For more information on eye

protection, click here.

Friday, September 28, 2012

Survey Shows Workers Avoiding Eye Protection

Chemical burns, blindness and scrapes are just a few the hazards workers face while not

using PPE on the job. Despite these grave risks, 85% of industrial workers in a

recent Kimberly-Clark Professional survey said they had observed others failing

to wear eye protection when they should have been. "The results are very

disconcerting when you consider that 90% of eye injuries can be

prevented through the use of proper protective eyewear,” says Valona

Renner-Thomas, Product Manager at Kimberly-Clark Professional. What is ironic

is that eyewear came in first when respondents were asked to rank the most

important PPE category for on-the-job safety. It was also deemed the “most

challenging" PPE category in terms of compliance. When asked what would most improve compliance

with eye protection protocols, the top choice was more comfortable eyewear

(56%) followed by fog-free lenses (22%). These alarming statistics should raise

a red flag for employers. Increased workers’ compensation costs and injuries

can result from even a slight eye injury. For more information on eye

protection, click here.

Chemical burns, blindness and scrapes are just a few the hazards workers face while not

using PPE on the job. Despite these grave risks, 85% of industrial workers in a

recent Kimberly-Clark Professional survey said they had observed others failing

to wear eye protection when they should have been. "The results are very

disconcerting when you consider that 90% of eye injuries can be

prevented through the use of proper protective eyewear,” says Valona

Renner-Thomas, Product Manager at Kimberly-Clark Professional. What is ironic

is that eyewear came in first when respondents were asked to rank the most

important PPE category for on-the-job safety. It was also deemed the “most

challenging" PPE category in terms of compliance. When asked what would most improve compliance

with eye protection protocols, the top choice was more comfortable eyewear

(56%) followed by fog-free lenses (22%). These alarming statistics should raise

a red flag for employers. Increased workers’ compensation costs and injuries

can result from even a slight eye injury. For more information on eye

protection, click here.

Wednesday, September 26, 2012

Transferring Flammable/Combustible Materials Safely

Newson Gale has published a white paper that provides detailed,

practical guidelines to ensure safe transfer of flammable or combustible products

to or from tanker trucks or similar mobile equipment. Titled “Achieving Safe Tanker Truck Loading / Unloading,” this

free paper informs readers on how high-voltage electric charges can be generated

when some liquids or powders come into contact with conductive objects. In

addition, it contains the three most current guidelines that protect against

this danger by ensuring that the feed system is securely grounded before and

during the transfer process. To download the paper, click here.

EPA Challenge to Increase Recycling of Used Electronics

EPA's Sustainable Materials Management (SMM) Electronics Challenge aims to change the way people think about protective electronics refurbishing and recycling practices and make them the industry standard. As the amount of used electronics increases, the importance of managing and recycling those electronics increases, as well.

Through the challenge, EPA reports, industry leaders are committing to send all of the used electronics

they collect to third-party certified refurbishers and recyclers. "The SMM Electronics Challenge will help us ensure that we are doing all we can to repurpose or safely dispose of the cell phones, computers and other devices we use every day, all while helping to build a robust market for electronics recylcing in the U.S.," says EPA Administrator Lisa Jackson.

Through the challenge, EPA reports, industry leaders are committing to send all of the used electronics

they collect to third-party certified refurbishers and recyclers. "The SMM Electronics Challenge will help us ensure that we are doing all we can to repurpose or safely dispose of the cell phones, computers and other devices we use every day, all while helping to build a robust market for electronics recylcing in the U.S.," says EPA Administrator Lisa Jackson.

Tuesday, September 25, 2012

Scholarships and Grants From the ASSE Foundation

The ASSE Foundation proudly announces its “2013

Scholarship & Professional Education Grant Program. ” Thanks to our generous donors, we are providing over $180,000 in scholarships and grants to students pursuing EHS degrees and to ASSE members and professionals working to advance their credentials. To apply visit: http://www.asse.org/foundation/application/. Applications are due Dec.1, 2012, and award recipients

will be announced on or around April 1, 2013. Good luck!

Organizations Recognized for Their Efforts in Green Power

EPA has honored several organizations for their achievements in using renewable electricity or green power. The agency reports that electricity is the single-largest producer of greenhouse gas emissions and green power can immensely help reduce those emissions and improve community health. EPA defines green power as "electricity generated from renewable resources, such as solar, wind, geothermal, biogas and low-impact hydro, and produces no net increase of greenhouse gas emissions."

Visit EPA to see the complete list of organizations that were honored.

Visit EPA to see the complete list of organizations that were honored.

Monday, September 24, 2012

Cartoon Character Educates Children on EHS

EU-OSHA has made its way into

children’s hearts with Napo, the cartoon character that teaches basic health

and safety knowledge at the primary school level. As part of a series of free

OSH education toolkits provided by the Napo Consortium and EU-OSHA, Napo covers topics that children aged 7 to

11 are likely to encounter at home and at school, including safety signs, risks

to the skin and back, and the identification of risks and hazards. The

educational aids come with lesson plans, suggested activities and accompanying

downloadable resources, and are intended to guide teachers on how to incorporate OSH messages

into existing curriculum. For more information and to download the toolkit, click here.

Friday, September 21, 2012

Starkey Hearing Foundation Teams with Scholastic to Promote Youth Hearing Protection

Starkey Hearing Foundation and Scholastic have partnered to develop classroom materials and a public service video to promote the message to American youth that "Hearing is fragile. So don't listen loudly. Listen Carefully."

Children and teens are at an increased risk of hearing loss. Listening to music and playing video games at dangerously high levels, Starkey says, is the primary culprit. In fact, one in five teens suffers from noised-induced hearing loss caused by improper use of personal listening devices--a 31% increase since the mid-1990s.

In response to these alarming statistics, the two organizations developed the Listen Carefully Teaching Guide, which is designed to teach students in grades 6 through 8 about the science of hearing while also allowing them to perform hearing-related experiments. Educators can access the free materials online.

Children and teens are at an increased risk of hearing loss. Listening to music and playing video games at dangerously high levels, Starkey says, is the primary culprit. In fact, one in five teens suffers from noised-induced hearing loss caused by improper use of personal listening devices--a 31% increase since the mid-1990s.

In response to these alarming statistics, the two organizations developed the Listen Carefully Teaching Guide, which is designed to teach students in grades 6 through 8 about the science of hearing while also allowing them to perform hearing-related experiments. Educators can access the free materials online.

ASSEF's Liberty Mutual Fellowship Program Is Open for Applications

ASSE Foundation is accepting applications for its 2013 Liberty Mutual Fellowship Program. The program aims to encourage research in the safety field; provide a forum for connecting safety professionals, industry needs and quality research programs; familiarize graduate students and faculty with current research models; and to lay groundwork for graduate students and faculty members to purse SH&E applied research projects of their interest.

ASSE Foundation is accepting applications for its 2013 Liberty Mutual Fellowship Program. The program aims to encourage research in the safety field; provide a forum for connecting safety professionals, industry needs and quality research programs; familiarize graduate students and faculty with current research models; and to lay groundwork for graduate students and faculty members to purse SH&E applied research projects of their interest.The program is available for those with a doctoral degree or those who are currently working towards a master's or doctorate degree. Applications for the summer 2013 program are due Feb. 1, 2013.

Thursday, September 20, 2012

Promoting Safety Culture

The Utilities Branch recently interviewed Michael Caro, director of safety and training for UtilX Corp., headquartered in Kent, WA. In the interview, Caro discusses approaches to safety training for electric utility workers and explains how UtilX promotes its safety culture throughout the company.

Click here to read the full interview.

Click here to read the full interview.

ASSE Accepting Entries for Kids' Poster Content

|

| Winners of last year's Safety-on-the-Job kids' poster contest were featured on the NAOSH Week 2012 poster. |

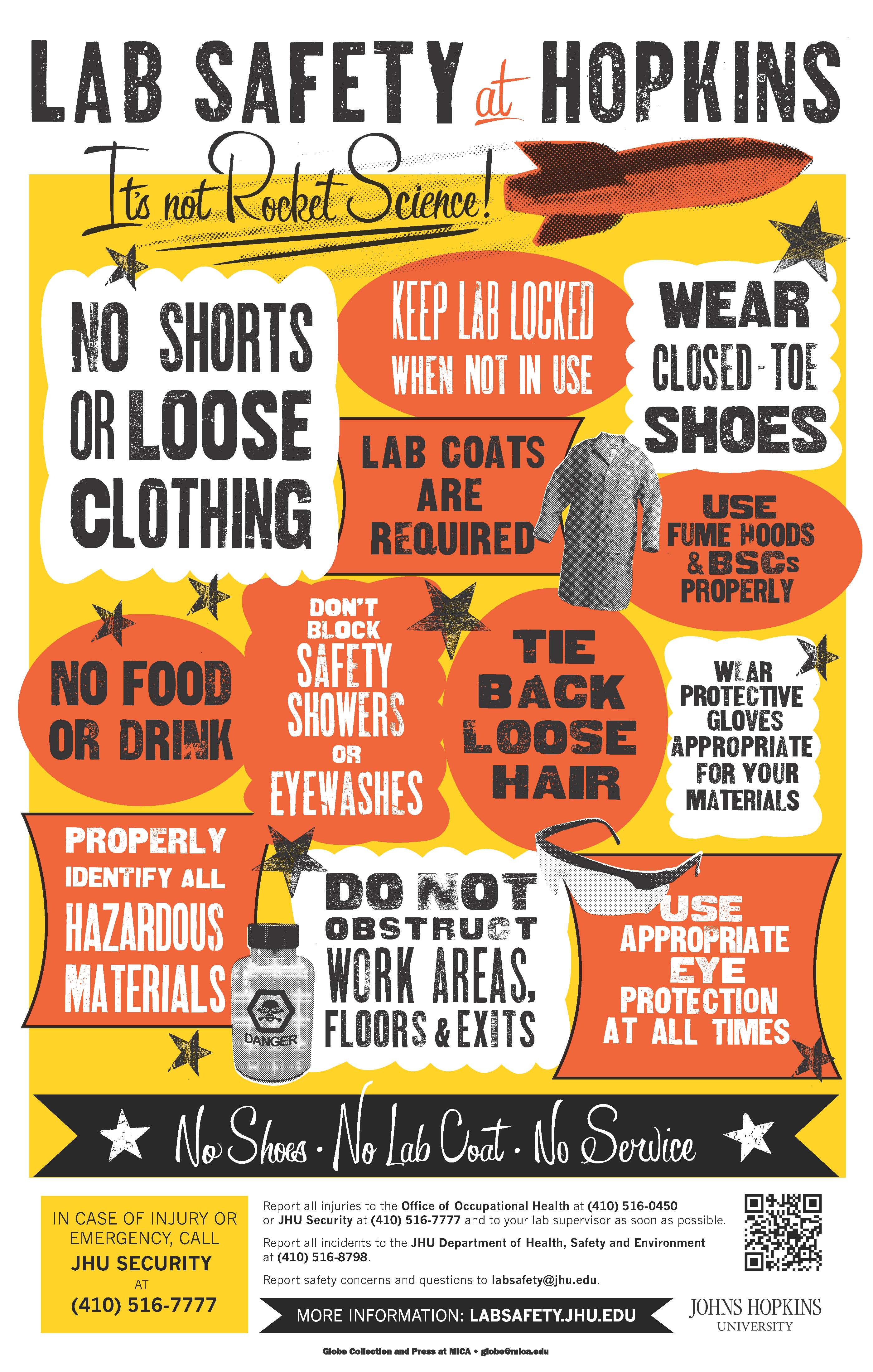

Johns Hopkins and MICA Promote Lab Safety

In an innovative partnership, Johns Hopkins University and the Maryland Institute College of Art (MICA) have teamed up to produce a retro-style poster to educate students about the importance of safety when working in research labs.

In an innovative partnership, Johns Hopkins University and the Maryland Institute College of Art (MICA) have teamed up to produce a retro-style poster to educate students about the importance of safety when working in research labs.The poster is designed in the style made famous by Globe Poster Printing Corp., a defunct Baltimore poster company that produced colorful concert advertisements promoting concerts from the 60s and 70s. MICA acquired many of the company's assets, creating the Globe Collection and Press at MICA, and is the new home for the tools used to create the posters, including thousands of pieces of wood type and boxes of hand-carved illustrations.

According to Johns Hopkins, the collaboration was a natural one for the two schools. While Johns Hopkins was looking for a catchy way to remind students about the importance of lab safety, MICA was working to integrate the historic collection into its curriculum. The two institutions joined forces with safety experts from Johns Hopkins, who supplied the lab safety do's and don'ts, and MICA students designed the poster that declares "Lab Safety--It's Not Rocket Science."

Wednesday, September 19, 2012

ISEA to Hold PPE Forum on Top 10 OSHA Violations

On Oct. 23, 2012, International Safety Equipment Association (ISEA) will hold its second annual forum focusing on how to prevent the top 10 OSHA violations. The forum will be held at the National Safety Council Expo in Orlando, FL. Following the presentation, experts from ISEA member-companies will explain what the association and equipment manufacturers are doing to improve safety for workers. Topics include respiratory protection, fall protection and eye/face protection.

Worker Safety & Health Challenge Deadline Extended

The deadline for submissions to DOL's Worker Safety and Health challenge has been extended until Nov. 30. The challenge is to develop tools to educate young workers on safety and health hazards, what they can do to protect themselves and their rights in the workplace.

According to DOL, successful entries could take many different forms: interactive and informative games, social or professional networking sites, or data visualization tools that teach young people about safety and health hazards. Submissions may be designed for Internet browsers, smartphones, feature phones, social media platforms, or as native Windows or Macintosh applications.

A panel of judges will award $15,000 for the "Safety in the Workplace Innovator Award," $6,000 for the "Safety and Health Data Award" and $6,000 for the "Workers' Rights Award." There is also a "People's Choice Award" of $3,000 for the developer of the app that receives the most public votes on the website.

Watch a short video here, visit the challenge page, and read OSHA Chief David Michaels’ most recent blog.

A panel of judges will award $15,000 for the "Safety in the Workplace Innovator Award," $6,000 for the "Safety and Health Data Award" and $6,000 for the "Workers' Rights Award." There is also a "People's Choice Award" of $3,000 for the developer of the app that receives the most public votes on the website.

Watch a short video here, visit the challenge page, and read OSHA Chief David Michaels’ most recent blog.

Farm Safety and Health Week

In

honor of this year’s National Farm Safety and Health Week taking place this

week, the Carle Center for Rural Health and Farm Safety has provided safety

tips for farmers of all ages.

- Children: Always get permission to visit a parent or adult while working on machinery, and remain in a visible area.

- Teens: Don’t use a cell phone when working; however, keep it close in case of an emergency.

- Adults: Keep the rollover protection structures in the upright position and always wear a seat belt to prevent a tractor rollover injury or fatality. Always wear hearing protection as well.

- Elderly: Take caution when lifting heavy items or climbing in unsafe areas, and recognize personal health and safety to avoid injury.

For

many long-time farmers, the safety and the dangers of agriculture are learned,

but often overlooked. “All it takes is one incident,” says Amy Rademaker,

farm safety specialist at the Carle Center. “It’s essential parents teach their

children that safety is important and necessary on a farm. On the flipside,

kids and grandkids are the most impressionable and are often the best at

reaching mom and dad.” For a full list of safety tips, click here.

Tuesday, September 18, 2012

Agencies Partner to Improve Environmental Aspects of Sporting Industry

Green Sports Alliance and EPA are working together to address environmental issues concerning sports teams and venues. Both organizations sealed their agreement with a Memorandum of Understanding at the Second Annual Green Sports Alliance Summit, held in Seattle, WA.

The agencies will tackle problems such as water and energy conservation, waste management, and sustainability for teams, stadiums and venues. Green Sports Alliance's Martin Tull says that for success in this endeavor, teams and venues must begin to measure their environmental impact. "This deeper partnership with EPA will help provide our members with the tools and resources they need to establish baselines and support their continuous improvement in terms of performance and efficiency," Tull says.

The agencies will tackle problems such as water and energy conservation, waste management, and sustainability for teams, stadiums and venues. Green Sports Alliance's Martin Tull says that for success in this endeavor, teams and venues must begin to measure their environmental impact. "This deeper partnership with EPA will help provide our members with the tools and resources they need to establish baselines and support their continuous improvement in terms of performance and efficiency," Tull says.

Monday, September 17, 2012

The Safety Professional’s Role in ERM

Erike Young’s article, “The Safety Professional’s Role in ERM,” from the Vol. 12 No. 1 issue of the Risk Management/Insurance Practice Specialty’s publication RM/Insight asserts that safety is often viewed as a compliance function and not as an integral part of achieving an organization’s mission.

Young says that if safety professionals want an integral role in supporting their organization’s mission, they must demonstrate the value of efforts beyond compliance. They must also fully understand their roles in enterprise and traditional risk management. In what ways does your organization use risk assessments and other risk-based tools to achieve its mission and exceed compliance?

Young says that if safety professionals want an integral role in supporting their organization’s mission, they must demonstrate the value of efforts beyond compliance. They must also fully understand their roles in enterprise and traditional risk management. In what ways does your organization use risk assessments and other risk-based tools to achieve its mission and exceed compliance?

Wise Words from IMTS Conference

This year's International Manufacturing Technology Show in Chicago has been full of great advice for safety professionals and business leaders everywhere. Check out what some of the speakers have to say:

We need to align

safety and health with [an organization's] business strategy.

Kathy Seabrook, President, Global Solutions Inc.

Safety is a series of destinations.

Ed Foulke, former OSHA Administrator

Safety is a series of destinations.

Ed Foulke, former OSHA Administrator

EHS professionals must expand their

scope within their companies and show the value of safety to the CFO and CEO.

John Howard, NIOSH Director

A site manager has to care about

workers, workers’ families and human needs. Find your champion who can do that

very well and then benchmark off of that champion.

John Henshaw, former OSHA Assistant Secretary of Labor

Citizenship provides a framework that

allows internal EHS activities to be leveraged outside of facilities.

Jim Cross, Global Process Safety Director, Dow Corning

There is no better advocate for your wellness

program than to see senior management participate.

Kristin Berdelman, Benefits Director, ACCO

Brands

Change your agenda so that every meeting starts with safety.

Phil McIntyre, Director of Business Development, Milliken

When workers’ values align with leaders’ values, it empowers the worker to engage in the work process.

Richard Fulwiler, President, Technology Leadership Assoc.

You need to achieve engagement in safety before you can get their [employees'] commitment to move the business forward.

Tim Fazio as said to Richard Fulwiler

You need to achieve engagement in safety before you can get their [employees'] commitment to move the business forward.

Tim Fazio as said to Richard Fulwiler

Leadership is not about being perfect, leadership is about consistently getting better.

Terry Mathis, CEO, ProAct Safety

Friday, September 14, 2012

New Z10 Standard Approved

The newly revised standard, “American National Standard for Occupational Health and Safety Management Systems” (ANSI/AIHA/ASSE Z10-2012), was approved by the American National Standards Institute on June 27, 2012.

The American Industrial Hygiene Association (AIHA), past secretariat of the Z10 Accredited Standards Committee (ASC Z10), has relinquished all of its secretariats to ASSE, making ASSE Z10 ASC secretariat and copyright holder of the 2012 and 2005 versions of the Z10 standard.

The Z10 standard provides an overall blueprint for widespread benefits in health and safety, as well as in productivity, financial, performance, quality and other organizational and business objectives. The standard’s seven sections include Management Leadership and Employee Participation, Planning, Implementation and Operation, Evaluation and Corrective Action, Management Review. Appendices address roles and responsibilities, policy statements, assessment and prioritization, audit information and more.

The Z10 standard also provides critical management systems requirements and guidelines for improvement of occupational health and safety. Experts from labor, government, professional organizations and industry formulated this valuable standard after extensive examination of current national and international standards, guidelines and practices.

For more information, click here or here.

The American Industrial Hygiene Association (AIHA), past secretariat of the Z10 Accredited Standards Committee (ASC Z10), has relinquished all of its secretariats to ASSE, making ASSE Z10 ASC secretariat and copyright holder of the 2012 and 2005 versions of the Z10 standard.

The Z10 standard provides an overall blueprint for widespread benefits in health and safety, as well as in productivity, financial, performance, quality and other organizational and business objectives. The standard’s seven sections include Management Leadership and Employee Participation, Planning, Implementation and Operation, Evaluation and Corrective Action, Management Review. Appendices address roles and responsibilities, policy statements, assessment and prioritization, audit information and more.

The Z10 standard also provides critical management systems requirements and guidelines for improvement of occupational health and safety. Experts from labor, government, professional organizations and industry formulated this valuable standard after extensive examination of current national and international standards, guidelines and practices.

For more information, click here or here.

Understanding the Increased Focus on Enforcement by Federal OSHA

From ASSE's Government Affairs Update

Recognizing ASSE members’ responsibility for managing interactions with OSHA for their employers, ASSE's Government Affairs Committee want its members and the SH&E community to understand the various administrative actions OSHA is taking to focus the agency’s enforcement efforts. Adele Abrams, Esq., ASSE’s federal representative, has prepared a summary of those actions to help ASSE members gain a broad understanding of how the current OSHA is undertaking its enforcement responsibilities. Find the document at Federal OSHA’s Increased Focus on Enforcement.Thursday, September 13, 2012

The Road to a Successful Safety Process

- Leadership expectations and communication. The best safety message a leader can give is "we don't want anyone to get hurt." Rather than making a case to workers that “it makes business sense to improve safety," this message shows workers that you actually care about their safety and health.

- Measurements and review. Measure and review safety mechanisms.

- Organization structure. Organizations should have subject matter expertise and code/compliance/auditing capability. The attitude that "I" own the safety process is critical as well.

- Reporting. The organization's agenda should start with safety. Make it a top priority in reporting.

- Standardization. McIntyre asks: How do you have a global, diverse, multifaceted company where individuals have the autonomy to make changes and change safety while staying tethered to standardization? This is a challenge each organization must learn to overcome. With the exception of some flexibility, organizations should remain standardized in their safety efforts.

- Time and dollar commitment. Invest in safety before incidents occur.

- Education. Train! Train! Train! Companies should institute training modules, code and compliance guidelines and other educational programs.

- Case management. If an incident at Milliken, a manager goes with the associate to the hospital. Management is on the scene from the moment an injury occurs until it is resolved.

- Awareness activities. Install activities, programs and even attitudes that continually keep the workers engaged.

Obese Workers: Health Issues and Rising Costs

Obesity is one of the biggest issues companies face in reducing injuries, according to former OSHA director Ed Foulke, at this year's International Manufacturing Technology Show in Chicago. Obesity in the workplace has gone up and will continue to rise with obese teenagers entering the workforce down the line, he adds. From type 2 diabetes and hypertension to cardiovascular problems and cancer, no company will be exempt from the rising number of health issues and workers' compensation costs. If obesity remains a concern, which it looks like it will, then workers will get injured easier and more frequently, with longer recovery times, Foulke says. If businesses can figure out how to address these issues now, then they will have less problems in the future.

Wednesday, September 12, 2012

College Students: Enter EPA's Campus RainWorks Challenge

EPA's Campus RainWorks Challenge invites college and university students to design a green, innovative water infrastructure project for their campus. Students are encouraged to use green infrastructure (e.g., vegetation, soils and natural processes) to help manage stormwater and address related water resource issues. The agency hopes to engage those interested in urban planning, design and engineering green solutions.

Registration is open until Dec. 14, 2012.

Registration is open until Dec. 14, 2012.

The Importance of Valuing Employees

Value each worker’s input. “You don’t want to do anything

unless it adds value,” says former OSHA Assistant Secretary of Labor John Henshaw, in today's panel discussion at the International Manufacturing Technology Show in Chicago. Managers must engage their workers and make

them feel needed and appreciated in order to gain employee commitment, he adds.

This will ensure higher productivity and a stronger dedication to the safety

process.

The key characteristic at successful companies is that "as many people as possible are engaged in understanding what their job is and own their own safety and health,” rather than just following the rules and owning the outcomes, Henshaw says.

According to Henshaw, successful engagement “comes down to the right people at the sites.” When it comes to choosing site managers, choose someone trustworthy and caring, he adds. A site manager has to care about workers, workers’ families and human needs. “Find your champion who can do that very well and then benchmark off of that champion,” Henshaw adds. “Showcase those skills so the other managers can see what’s valued in a company.”

The key characteristic at successful companies is that "as many people as possible are engaged in understanding what their job is and own their own safety and health,” rather than just following the rules and owning the outcomes, Henshaw says.

According to Henshaw, successful engagement “comes down to the right people at the sites.” When it comes to choosing site managers, choose someone trustworthy and caring, he adds. A site manager has to care about workers, workers’ families and human needs. “Find your champion who can do that very well and then benchmark off of that champion,” Henshaw adds. “Showcase those skills so the other managers can see what’s valued in a company.”

Be an Effective Safety Leader

- Setting a bad example

- Creating resistance

- Avoiding failure

- Managing results instead of performance

- Thinking it is about “me”

- Failing to coach

- Put hearts before minds. Get people emotionally involved and inspired, then their minds will follow.

- Don’t treat employees like children; instead, show them respect.

- Manage performance before results. Leaders should ask, “What’s the strategy to improve safety?”

- Avoid failures by reviewing incident rates, setting the goal for new incident rates, developing lists of initiatives and executing those initiatives.

- Don't confront employees. This is nonproductive on the job. Finding out “why” is incredibly productive.

- Acknowledge and appreciate an employee’s hard work. Be thankful.

- Know and believe in this truism: “You don’t succeed by being a great leader; you succeed by leading great people.”

Safety Communication Addresses Blunt-Tip Surgical Suture Needles

U.S. Food and Drug Administration, NIOSH and OSHA, posted a joint safety communication encouraging healthcare professionals in surgical settings to use blunt-tip suture needles to suture muscle and fascia, when clinically appropriate, to reduce the risk of needlestick injury and subsequent pathogen transmission.

Needlestick injuries continue to occur in surgical settings when suturing muscle and fascia, despite the availability of safety-engineered devices, such as blunt-tip suture needles, and the endorsement of their use by professional organizations. Needlestick injuries have the potential to expose healthcare personnel to bloodborne viruses, such as hepatitis B virus, hepatitis C virus and human immunodeficiency virus.

The American College of Surgeons recommends the universal adoption of blunt-tip suture needles as the first choice for the closure of fascia and muscle. This statement is endorsed by the Association of periOperative Registered Nurses, American Association of Nurse Anesthetists, American Association of Surgical Physician Assistants, American Society of Anesthesiologists, American Society of PeriAnesthesia Nurses and Association of Surgical Technologists. The 2011 Viral Hepatitis Action Plan also recommends the use of blunt-tip suture needles to help reduce device-related needlestick exposures among healthcare personnel.

Find OSHA's information on bloodborne pathogens and needlestick prevention here; FAQs about the Needlestick Safety & Prevention Act here; a CDC health bulletin here; and an FDA report on medical device reporting guidance here.

Needlestick injuries continue to occur in surgical settings when suturing muscle and fascia, despite the availability of safety-engineered devices, such as blunt-tip suture needles, and the endorsement of their use by professional organizations. Needlestick injuries have the potential to expose healthcare personnel to bloodborne viruses, such as hepatitis B virus, hepatitis C virus and human immunodeficiency virus.

The American College of Surgeons recommends the universal adoption of blunt-tip suture needles as the first choice for the closure of fascia and muscle. This statement is endorsed by the Association of periOperative Registered Nurses, American Association of Nurse Anesthetists, American Association of Surgical Physician Assistants, American Society of Anesthesiologists, American Society of PeriAnesthesia Nurses and Association of Surgical Technologists. The 2011 Viral Hepatitis Action Plan also recommends the use of blunt-tip suture needles to help reduce device-related needlestick exposures among healthcare personnel.

Find OSHA's information on bloodborne pathogens and needlestick prevention here; FAQs about the Needlestick Safety & Prevention Act here; a CDC health bulletin here; and an FDA report on medical device reporting guidance here.

Tuesday, September 11, 2012

The Power of Transformational Leadership

According to Fulwiler, there are two types of leaders: transactional and transformational. Transactional leaders operate from command-control mode. They focus on costs and financial goals, and have a quid pro relationship with their workers. “This will get you average,” Fulwiler adds.

On the other hand, transformational leaders operate from a collaborative mode. They lead by influence, encourage employee involvement and team building, and genuinely care about worker wellness. “This is the key to productivity and high performance work systems,” Fulwiler says, adding that this leads to above average outcomes. He describes five key characteristics that make up a transformational leader:

- Listen: Seek first to understand then to be understood. Listen for meaning and feeling (empathetic listening), not just facts.

- Communicate: Speak in a language that your workers can understand. Be open to feedback and to criticism.

- Care: Visibly demonstrate that you really care about the your employees' safety and health.

- Be collegial: Interact and relate employees on all levels. Try to make workers feel at ease.

- Engage: Convey a sense of worth to the workers. Link the workers' needs with the company’s needs.

Safety Performance & Leading Indicators

Businesses that use leading indicators (rather than lagging indicators) can better spot problem areas and take action before someone gets hurt, non-compliance occurs, a client is disappointed or the EHS culture/reputation is negatively affected, says Fluor Corp. HSE Vice President Jeff Ruebesam, at this year's International Manufacturing Technology Show in Chicago. Leading indicator metrics include training, safety task assignments (What are the hazards? How to combat them?), hazard recognition and elimination, management participation, weekly inspections, near-miss reporting (be sincere, take away the fear that employees have with reporting and make it easy to report), and trending and tracking.

Ruebesam adds that three important factors contribute to a successful site leading indicator program:

- Craft: Build trust, raise awareness and engage everyone. “Employees see everything and they talk,” he says. “You can build a bad counterculture if management is not sincere.”

- Programs: Use effective data collection, analysis and corrective measures. “It’s not so much getting feedback from the people but it’s what you do with it after you get it,” he says.

- Leadership: Gain buy-in, utilize active program participation and be consistent in actions.

Joint Commission Rolls Out Worker Flu Vaccine Policies

The Joint Commission R3 Report provides information about the 2012 flu vaccine requirement. “The organization states that although vaccination is the “single most effective method” for preventing influenza deaths and illnesses, the Department of Health and Human Services reports that vaccination rates for healthcare professionals remain below 60%. Learn more here.

Monday, September 10, 2012

Health Implications: Sitting & Standing While At Work—Which Is Better?

In “Which is Better, Sitting or Standing?” Humantech’s Blake McGowan, CPE, notes that while standing at work seems to be gaining favor, the health implications associated from standing too much may be being overlooked. “Before we all get rid of our office chairs, we may want to understand the health consequences associated with prolonged standing which include work-related musculoskeletal disorders in the legs, knees and lower back; varicose veins; joint damage; foot problems; stroke; heart and circulatory problems; and pregnancy difficulties.” However, McGowan also points to the well-documented health consequences associated with prolonged sitting, such as higher rates of cardiovascular disease; obesity; higher body mass index; deep venous thrombosis; and low-back disorders.

“It is not an ‘either-or’ situation. A more responsible approach is to recommend a combination of sitting and standing activities throughout the work day to minimize the potential for adverse health consequences associated with both postures,” says McGowan. He offers these proposed guidelines for sit/stand workstations:

“It is not an ‘either-or’ situation. A more responsible approach is to recommend a combination of sitting and standing activities throughout the work day to minimize the potential for adverse health consequences associated with both postures,” says McGowan. He offers these proposed guidelines for sit/stand workstations:

- Limit continuous (static) sitting to 4 hours per day.

- Limit continuous (static) standing to 1 hour per day.

- Limit cumulative standing to 4 hours per day.

- Promote variation between sitting and standing positions throughout the day.

- Design the workstation for active movement while sitting and standing.

Friday, September 7, 2012

Safe Use of Mechanical Lifting System

Research

shows that mechanical lifting systems used in hospitals, care facilities and

private homes have been the source of injury, and even death, to clients and

attendants, according to a hazard

alert from Nova Scotia. These incidents are mainly related to the

malfunction, failure or misuse of patient lifts, and new hazards include

falling suspended parts, dropped loads, equipment failure, structural failure

and electric shocks. Body strain is also a risk if the hoist should fail and an

attendant tries to catch a falling client. The following tips from the FDA

and Nova

Scotia offer practical guidance to help prevent injuries to attendants

using patient lifts.

- Be trained on

and understand how to operate the lift.

- Fasten all

clips, latches and hanger bars securely during operation.

- Keep the base

(legs) of the patient lift in the maximum open position and position the

lift to provide stability.

- Ensure the

patient's arms are inside the sling straps.

- Lock the wheels

on any device that will receive the patient such as a wheelchair,

stretcher, bed or chair.

- Ensure that the

weight limitations for the lift and sling are not exceeded.

- Follow the

instructions for washing and maintaining the sling.

- Follow a

maintenance safety inspection checklist to detect worn or damaged parts

that need immediate replacement.

The

hazard alert adds that because slings are a key part of the lifting system, it’s

essential to use the correct sling for the specific hoist. The safe working

load must be clearly marked on both the lift and the sling. Inspect the sling

fabric and straps to make sure they are not frayed or stressed at the seams, and if there are signs of wear, do not use it. The

manufacturer's specifications will likely provide a frequency for periodic

inspections and pre-use inspections. These inspections help to identify any

visible signs of damage to equipment that may lead to a failure. For more

information, click here.

Thursday, September 6, 2012

NIOSH/OSHA Fall Prevention Campaign

“Safety pays. Falls cost.” That’s the slogan of the new

national fall prevention campaign launched by NIOSH, OSHA, CPWR and the NORA

Construction Sector Council. According to the BLS, more than 10,000

construction workers were hurt and another 225 killed at work in 2010 after

falling from a height. In fact, falls from heights cause the second-highest

rate of nonfatal injuries and illnesses resulting in days away from work. Offering

both an abundance of resources and volunteer opportunities, the new campaign

hopes to lower these numbers with three simple steps to preventing falls: plan,

provide and train. For more information or to join the campaign, visit www.stopconstructionfalls.com.

Check Out DOE's Photo of the Week

Each week, U.S. Department of Energy (DOE) highlights an energy-related photo on its website, Facebook, Twitter and Flickr. The photos are favorite energy-related picks by agency employees. Check out this week's photo of the first digital computer at Argonne National Laboratory.

Wednesday, September 5, 2012

Manual Material Handling Limits for Industrial Athletes

Kent Hatcher’s article “Manual Material Handling: Why Do We Need Limits?”, from the latest issue of the Ergonomics Practice Specialty's publication Interface, highlights the importance of building a conceptual bridge between the athletic performance of an Olympian and the work performance of an industrial “athlete.”

Hatcher advises that corporate ergonomists and plant safety professionals consider their specific industry, task and environment before making recommendations to improve lifting tasks. Click here to read his tips for safely optimizing workforce performance.

Hatcher advises that corporate ergonomists and plant safety professionals consider their specific industry, task and environment before making recommendations to improve lifting tasks. Click here to read his tips for safely optimizing workforce performance.

New Chemical Database Defines Health Effects

The International Union of Electronic,

Electrical, Salaried, Machine and Furniture Workers, in collaboration with BlueGreen Alliance, has released a tool that

allows workers to look up both the acute and chronic effects of the 10,000 most

commonly used chemicals. The Chemical Hazard

and Alternatives Toolkit (ChemHAT) is a free online database featuring a

wide range of chemical health effects ranging from skin rashes and eye

irritants to birth defects, nervous system disorders and cancer. The

database also identifies how workers come into contact with the materials, what

available safety precautions they should take and what alternatives are

available.

Tuesday, September 4, 2012

Winning Strategies from the Olympic Build

The

health and safety techniques developed during the 2012 Olympic build can be mimicked in other construction projects to prevent injuries and fatalities, according

to a recent study by the Institution of Occupational Safety and Health (IOSH)

and the U.K. Health and Safety Executive. From the findings, IOSH identified

best practices in five key areas that could be used in construction

companies and projects of all sizes.

1.

Lead from the top.

Set standards and visibly engaged with the workforce to direct, motivate and

change behavior by focusing on its long-term goals.

2.

Develop competent supervisors. Supervisors with technical,

interpersonal and communication skills are more effective in conveying health

and safety messages.

3.

Foster an open, positive safety culture. Workers must be able to communicate problems without fear of retribution. Workers who feel

that managers care about them are more likely to get involved with the health

and safety process.

4.

Reward good behavior. Incentives and rewards helped to promote and encourage

safe and good behaviors such as reporting near misses. In many cases,

positive feedback was the real reward, as it boosted morale.

5.

Review and learn.

Review any problems constantly and communicate them across the organization.

Most importantly, use the lessons learned from the problems encountered to

improve health and safety.

According

to Olympic Delivery Authority, an estimated 40,000 people worked on the build of the Olympics, and

not one fatality was recorded during the construction phase. For more

information, visit Lessons learned from the London 2012 Games construction

project.

|

OSHA Extends Enforcement Rules in Residential Construction

OSHA has decided to extend its temporary enforcement measures in residential construction for 3 more months. This will extend the measures until Dec. 15, 2012. According to the agency, the enforcement rules include priority free on-site compliance aid, penalty reductions, rules to ensure consistency and increased outreach. OSHA also states that it will continue to work withe employers to ensure clarity of compliance policies.