Pages

▼

Monday, June 30, 2014

Safety 2015 Call for Presenters

ASSE is accepting proposals for Safety 2015, scheduled for June 7-10 in Dallas, TX. All proposals will be reviewed by ASSE's Conference Planning Committee, which is particularly interested in advanced, technically oriented and practical presentations. Proposals are due July 14, 2014, and notification of acceptance will be mailed by Nov. 13, 2014. Visit ASSE's website for submission instructions and for more information.

Wednesday, June 25, 2014

CPWR Hiring Director of Exposure Control Technologies Research

Center for Construction

Research and Training (CPWR) is seeking

qualified candidates to direct its Construction Solutions research project.

CPWR says preferred candidates will have knowledge of the construction

industry; experience in the conduct of applied construction research;

experience with exposure or risk assessment; and familiarity with evaluation of

measures to reduce exposures/risks. A terminal degree is highly preferred.

Excellent written and oral technical communication and analytical skills are

required, including peer-reviewed journal articles and grant writing.

Experience in research project management and staff supervision is expected.

Tuesday, June 24, 2014

NSC Poll: Most Want Stronger Enforcement of Texting & Driving

According to results of an NSC

public opinion poll, 73% of respondents think enforcement of texting laws

should be stronger, while 22% think enforcement is okay as is.

According to results of an NSC

public opinion poll, 73% of respondents think enforcement of texting laws

should be stronger, while 22% think enforcement is okay as is.

“For years, there has been widespread opposition to texting

behind the wheel,” says NSC’s Deborah Hersman. “Today, the polls show the

public is behind stronger penalties because most people recognize that it will

take more than awareness campaigns to stop this dangerous behavior.”

Despite people’s beliefs that they can multitask, NSC says, studies

show that hands-free

devices are no safer than handheld; the brain is still distracted when

talking on the phone.

NSC offers several distracted

driving resources:

- Posters, fact sheets

- YouTube videos

- Employer cell phone policy kit

- White papers on understanding the distracted brain, and distracted driving

- Annual estimate of cell phone crashes

ASSE offers several resources

as well, including articles,

presentations, tips and other tools from the SH&E Body of Knowledge.

Monday, June 23, 2014

Today: OSHA Talks With Teens About Workplace Violence Prevention

OSHA Administrator David Michaels will join a group of teen safety peer educators on a telephone press conference call today at 3 p.m. (EST). The call will focus on workplace violence prevention. With many teens seeking summer jobs this year, the issue of workplace violence is one that must be addressed and prevented. To listen in to the conversation, RSVP to jeff.newton@masscosh.org, then dial in toll-free to (800) 732-8470.

Friday, June 20, 2014

Be Lightning Aware

June 22-28, 2014, is Lightning Safety Awareness Week. The campaign aims to build awareness of lightning hazards and preparedness actions.

You can find lightning safety tips and other information about lightning at ready.gov/thunderstorms-lightning or download the free FEMA app, available for Android, Apple or Blackberry devices. National Weather Service also offers various resources to improve awareness in your community.

You can find lightning safety tips and other information about lightning at ready.gov/thunderstorms-lightning or download the free FEMA app, available for Android, Apple or Blackberry devices. National Weather Service also offers various resources to improve awareness in your community.

OSHA Issues Hazard Bulletin on Tree Care Work

OSHA has issued a hazard bulletin discussing two fatal tree care incidents to help prevent worker fatalities from falls and falling objects in tree care work. The bulletin also provides safety precautions for employers to use before they begin work:

- Assess the work site for fall and falling object hazards.

- Have a qualified arborist survey the work site.

- Determine f workers will need to climb or use aerial lifts.

- Establish drop zones where a falling object hazard exists.

- Protect workers from falling object hazards.

- Establish visual and audible communications with overheard and ground workers.

- Have emergency procedures in place.

Thursday, June 19, 2014

NIOSH Publication Offers Recommendations to Prevent Worker Injuries, Deaths in Road Construction

A new NIOSH Workplace Solutions addresses risks associated with roadway construction worksites.

Visit the NIOSH website for more information.

Data from the Bureau of Labor Statistics (BLS) indicates workers on roadway construction worksites are exposed to injury and death from moving construction vehicles and equipment. According a BLS review, 443 of the 962 fatal workplace injuries at road construction sites from 2003 to 2010, were due to a worker being struck by a vehicle or mobile equipment. Additionally, 143 workers were fatally struck by a vehicle or mobile equipment that was backing up.

“Preventing Worker Injuries and Deaths from Backing Construction Vehicles and Equipment at Roadway Construction Worksites,” offers recommendations for employers, contractors, workers and construction vehicle and equipment manufacturers to help prevent worker injuries and deaths from backing construction vehicles and equipment at roadway construction work sites.

The publication includes detailed lists of procedures and controls that the agency has identified to help protect workers from injury while working around backing construction vehicles and equipment on roadway construction worksites.

Visit the NIOSH website for more information.

Tuesday, June 17, 2014

2014 ASSE Safety Innovation Award Presented to Ali Hasan Al-Failakawi

At the Safety 2014 conference in Orlando, FL, last week, ASSE named Ali Hasan Al-Failakawi the winner of the 2014 Award for Innovation in Occupational Safety Management for implementing a road safety program that helped reduce motor vehicle incidents. The award was sponsored by Cintas Corp., provider of on-site safety services and training solutions.

A professional member of ASSE's Kuwait Chapter, Al-Failakawi is an occupational safety and health team leader for the Kuwait Oil Co., an oil and gas utility with more than 30,000 employees who travel more than 5 million miles each month. Al-Failakawi and his team initiated a program to promote safe driving. To develop the program, the team created a process called "SPEED-Management." SPEED is an acronym that describes a multi-directional approach covering the following areas:

"We're truly inspired by the unique strategies and programs that organizations have implemented in an effort to improve workplace safety," says 2013-2014 ASSE President Kathy A. Seabrook. "Al-Failakawi and his team stood out for their dedication to promote safe driving whether employees were working or off the clock."

"Every organization should make ongoing safety a priority and this award highlights the best programs and tools of today," says Cintas's Dan Braun. "We hope the ideas from the winner and honorable mentions encourage organizations to analyze their current safety programs and identify ways they can take them to the next level."

A professional member of ASSE's Kuwait Chapter, Al-Failakawi is an occupational safety and health team leader for the Kuwait Oil Co., an oil and gas utility with more than 30,000 employees who travel more than 5 million miles each month. Al-Failakawi and his team initiated a program to promote safe driving. To develop the program, the team created a process called "SPEED-Management." SPEED is an acronym that describes a multi-directional approach covering the following areas:

- Surveillance, including fleet controls and prevailing driving practices;

- Policies, suitable and appropriate;

- Engineering approach and solutions;

- Enforcement of rules and regulations;

- Driver awareness program.

"We're truly inspired by the unique strategies and programs that organizations have implemented in an effort to improve workplace safety," says 2013-2014 ASSE President Kathy A. Seabrook. "Al-Failakawi and his team stood out for their dedication to promote safe driving whether employees were working or off the clock."

"Every organization should make ongoing safety a priority and this award highlights the best programs and tools of today," says Cintas's Dan Braun. "We hope the ideas from the winner and honorable mentions encourage organizations to analyze their current safety programs and identify ways they can take them to the next level."

Emergency Response App Includes Real-Time Weather & Traffic Data

A new, free app from SAFER Systems, the SAFER Mobile Response, provides first responders with crucial information when called to the scene of an incident. The app includes the 2012 Emergency Response Guidebook (ERG2012), Google Maps, Google Traffic and live weather updates and forecasting. SAFER Systems President Allen Edmond says that the app takes the ERG2012 to the "next level" with its weather and traffic features. "It will help responders plan their way to the incident scene and identify key municipal amenities at risk," Edmond says.

The app is available for Android and Apple products and can be downloaded here.

The app is available for Android and Apple products and can be downloaded here.

Monday, June 16, 2014

Fall Protection: Plan, Provide & Train

On June 5, 2014, LJB Inc. presented Fall Protection Stand-Down: Plan, Provide, Train, a webinar to help

safety professionals address fall protection concerns. Thom Kramer, president

of International Society on Fall Protection, explained that to address fall

hazards, organizations must plan and be aware of risks; provide the right

equipment; and train workers in order to change behavior.

Plan

An effective way to start off the planning process may be to

ask the following questions:

•Have you thought through the work process?

•Have safe anchorage points been identified along the work

path?

•Have you accounted for all variables?

•Do you have all needed PPE?

•Do you have a complete fall protection system?

•Are the components compatible?

•Is there training that ties these components together?

According to Kramer, fall protection policies should

indicate that hazard identification, evaluation and control be performed for

all tasks with potential for falling a distance that meets or exceeds the

threshold height requiring fall protection. The general industry threshold

height is 4 ft, however, threshold heights vary by industry and application.

Planning must account for all aspects of a personal fall

arrest system. Anchor points should be pre-identified so that workers do not

need to take time to decide on anchor points during a task. Likewise, equipment

capabilities and clearance issues must be evaluated during the planning process

to help limit unforeseen challenges.

Provide

Kramer warns that merely providing harnesses is not enough.

PPE must be evaluated to ensure that it will be effective at the necessary

height. Elements to consider during this evaluation include the type of

lanyard, the anchorage location relative to the dorsal D-ring and any objects

located in the potential fall path.

Fall protection equipment must also be inspected regularly,

including daily pre-use inspections, formal inspections every 6-12 months and

incident investigation inspections.

“A lot of people are in the dark when it comes to how much

is too much deterioration,” says Kramer about the results of fall protection

equipment inspections. Signs of deterioration to watch for include frayed

thread, cuts, tears, heat exposure and discoloration. PPE must also be taken

out of service after an incident during which the PPE was worn.

Training

Kramer suggests consulting the ANSI/ASSE Z359 fall

protection code’s training requirements, adding that the standard’s list of 15

duties of a competent person may be especially helpful.

When preparing fall protection training strategies, certain training

options must be carefully considered. For example, while a classroom setting

may be appropriate for certain types of training, hands-on training is more

effective for equipment use and inspection training. Ensure that all

instructors are qualified, and determine forms of media to use based on your

audience and training content.

OSHA's Online Interactive Game Helps Users Identify Workplace Hazards

At Safety 2014, OSHA unveiled its new interactive online training tool to help small businesses effectively identify workplace hazards. OSHA's Hazard Identification Training Tool allows users to experience from the perspective of a business owner or employee while they identify realistic, common hazards and try to address the hazards with effective, practical solutions. As the agency reports, "The tool explains the key components of the hazard identification process, which include information collection, observation of the workplace, investigation of incidents, employee participation and prioritizing hazards."

To learn more about the game, view the YouTube trailer here.

To learn more about the game, view the YouTube trailer here.

Friday, June 13, 2014

Become a Steward of Safety

Many are still unaware of the number of workplace deaths that occur every day in the U.S.--12 people die every day at work. Vivid Learning Systems has launched a new initiative to raise awareness of this overlooked problem. The goal of the Stewards of Safety initiative is to encourage safety leadership. Participants are asked to pledge support, share the message socially and commit to spreading safety awareness.

Take the Stewards of Safety Pledge here.

The campaign was developed in collaboration with safety experts and industry veterans familiar with the spectrum of high-risk work. When you take the pledge to become a Steward of Safety, you receive a free kit including downloadable safety awareness assets.

"We are not making enough progress on reducing the number of these tragic events," says Vivid's Liz Bormida. "Without the involvement of the community and commitment from stakeholders, we cannot lower the number of serious injuries and fatalities for workers. If you're an American worker wanting to protect the future of our workforce, take the pledge and become a Steward of Safety."

After you take the pledge, follow the Stewards of Safety Fallen Worker Flipboard, read Vivid's blog, or sign up for the Stewards of Safety e-newsletter, and share articles that move you.

Take the Stewards of Safety Pledge here.

The campaign was developed in collaboration with safety experts and industry veterans familiar with the spectrum of high-risk work. When you take the pledge to become a Steward of Safety, you receive a free kit including downloadable safety awareness assets.

"We are not making enough progress on reducing the number of these tragic events," says Vivid's Liz Bormida. "Without the involvement of the community and commitment from stakeholders, we cannot lower the number of serious injuries and fatalities for workers. If you're an American worker wanting to protect the future of our workforce, take the pledge and become a Steward of Safety."

After you take the pledge, follow the Stewards of Safety Fallen Worker Flipboard, read Vivid's blog, or sign up for the Stewards of Safety e-newsletter, and share articles that move you.

Wednesday, June 11, 2014

Live From Safety 2014: Executive Insights on Safety

The popular Executive Summit was held today at ASSE's Safety 2014 in Orlando, FL. The summit gives OSH professionals an opportunity to hear from a panel of corporate executives about their thoughts about workplace safety and the business role of OSH professionals.

I've listened in to several of these panels over the years and today's group seemed among the most approachable and pragmatic. During the panel, each executive answered questions specific to his company and to his thoughts on workplace safety in general, providing attendees with takeaways and words of wisdom to consider as they return to their facilities with all the information gleaned from 3 days of concurrent education sessions at Safety 2014

Trevor Larsen, vice president, worldwide safety, WDP&R, Walt Disney Parks & Resorts: "We encourage our employees to have a lens on safety in everything they do."

Darron Anderson, CEO, Express Energy Services: "No different standards for the CEO."

John Gromos, vice president and general manager with Turner Construction: "Job sites change frequently, that's why culture is so important. We shouldn't have to tell someone what is a good action. They should see it on every site every day."

Mark Costello, general manager for the URS Industrial/Process Group: "One of my heroes is John Wooden. You can tell the character of who someone is when no one is looking. Have to empower people to make the right choice when they have to."

And a few more:

I've listened in to several of these panels over the years and today's group seemed among the most approachable and pragmatic. During the panel, each executive answered questions specific to his company and to his thoughts on workplace safety in general, providing attendees with takeaways and words of wisdom to consider as they return to their facilities with all the information gleaned from 3 days of concurrent education sessions at Safety 2014

Here's are just a few highlights from the session:

Jeff Smith, deputy director of operations, Oak Ridge National Laboratory: "I'm not a banner and slogan guy. It's not what people see it's how people behave that shows folks what we do."

Darron Anderson, CEO, Express Energy Services: "No different standards for the CEO."

Mark Costello, general manager for the URS Industrial/Process Group: "One of my heroes is John Wooden. You can tell the character of who someone is when no one is looking. Have to empower people to make the right choice when they have to."

And a few more:

Darron Anderson, CEO, Express Energy Services: "No dollar value worth getting hurt."

Mark Costello, general manager for the URS Industrial/Process Group: "What creates safety performance creates business performance."

Trevor Larsen, vice president, worldwide safety, WDP&R, Walt Disney Parks & Resorts: "Harness the power of storytelling."

Mark Costello, general manager for the URS Industrial/Process Group: "What creates safety performance creates business performance."

Trevor Larsen, vice president, worldwide safety, WDP&R, Walt Disney Parks & Resorts: "Harness the power of storytelling."

John Gromos, vice president and general manager with Turner Construction: "Complacency is a dangerous thing. Remind everyone that it's because of hard work and focus that we have these results. It has to happen every single day."

Jeff Smith, deputy director of operations, Oak Ridge National Laboratory: "Recognize that it's your mission to support and enable the research by protecting the asset. Be perceived as an enabler not a roadblock."

Jeff Smith, deputy director of operations, Oak Ridge National Laboratory: "Recognize that it's your mission to support and enable the research by protecting the asset. Be perceived as an enabler not a roadblock."

As a group, the panelist also agreed with Costello's idea that OSH professional need to "build on the positive as a force mulitlipier." As Larsen said, "When out in an operation, don't just tell them something is wrong. Give them an alternative. Instead of being feared, be sought out." Anderson also advised OSH professionals to understand the moment and whether it's best to be a leader, partner or cheerleader. "Know what's happening on a particular day and figure how to best support it at that given time."

Live From Safety 2014: The Ergo (Safety) Hour

Many OSH professionals work or consult for multinational organizations, which introduces challenges related to culture, language, understanding and a host of other issues. During their concurrent education session at ASSE's Safety 2014 in Orlando, FL, Dan Johnson (BorgWarner) and Jeremy Wilzbacher (AON) shared some practical ideas for spreading organizational learning and best practices to global facilities.

The foundation of their approach is something they have labeled "The Ergo Hour." At its most basic, Ergo Hour is a webinar during which the organization educates workers in different locations on specific ergonomics topics. Viewed beyond those parameters, Ergo Hour is about engagement, active learning and information sharing--and the concept is transferable to a variety of OSH topics.

Several core elements drive the process:

- Assess needs.

- Provide a structure (e.g., a safety management system).

- Ensure continuous contact.

- Deliver efficient technical support.

- Implement at the plant level.

According to Wilzbacher, webinars can take many forms. Some are used to present a new topic, while others highlight plant-specific ergonomics projects in order to share knowledge about specific exposures identified and addressed. Wilzbacher and Johnson noted that the webinar format makes the education available at the individual level as well as the team level. It also enables the company to share information visually--including key measurements and parameters--so that many individuals can readily understand, regardless of their background, education or language.

Wilzbacher and Johnson also offered these suggestions for ensuring that the webinar has maximum impact:

- Make your content visual.

- Capsulize in easy-to-understand terms what is being discussed.

- Explain how to conduct and score an ergonomic assessment.

- Include before and after photos that illustrate the anthropometric issues of concern.

- Highlight pertinent section of assessment results

- Ask questions to get participants involved.

- Incorporate videos where able.

The format sets up an interactive process that generates continued contact, Wilzbacher explained. He often hears from a plant representative about a key concern, then asks that individual to share video, photos and data about this issue. He then reviews that information and starts an ongoing dialogue with the facility that leads to sharing of lessons learned and employee engagement. It also helps plant personnel recognize that they aren't the only ones ergonomic challenges. This begins to propel a learning and sharing environment.

Live From Safety 2014: Dispelling Myths About Human Error

Post by Safety 2014 Guest Blogger Frank D'Orsi, CSP, ARM

During his concurrent education session at ASSE's Safety 2014 in Orlando, FL, Rick Pollock, ASSE's 2012-13 president and president of ASSE centennial sponsor CLMI, shared some interesting thoughts on human error and myths that that surround it in determining injury causation. He explained that most human mistakes happen based on the way our brains handle information, not because we are careless or stupid. The mistakes we make most often are not choices, Pollock explained. We don't choose to make mistakes, be unsafe or ignore our training. The reason people make mistakes is because we often cannot perceive the outcome or what can potentially occur, he said.

During his concurrent education session at ASSE's Safety 2014 in Orlando, FL, Rick Pollock, ASSE's 2012-13 president and president of ASSE centennial sponsor CLMI, shared some interesting thoughts on human error and myths that that surround it in determining injury causation. He explained that most human mistakes happen based on the way our brains handle information, not because we are careless or stupid. The mistakes we make most often are not choices, Pollock explained. We don't choose to make mistakes, be unsafe or ignore our training. The reason people make mistakes is because we often cannot perceive the outcome or what can potentially occur, he said.

Rick also discussed application of Deming's principles to safety and injury causation and highlighted why we can't punish away error. Another key consideration is hindsight bias, which Rick defined as the illusion of free will. He noted that a focus on human preconditions often blocks investigators efforts to identify actual causation.

To effect change and reduce human error, OSH professionals must address various elements, including behavior-based safety, organizational culture and climate, and systems design. We need to understand the underlying factors such as:

To effect change and reduce human error, OSH professionals must address various elements, including behavior-based safety, organizational culture and climate, and systems design. We need to understand the underlying factors such as:

- complacency not being a choice but a condition that exists when it's felt that the work task has been mastered and known;

- work deviation;

- habit development;

- normalized deviation drift;

- poor design that provokes human error.

We need to counter the factors with systems and risk assessment, prevention through design and sustainability.

Live From Safety 2014: A Technical Tour of Cirque du Soleil

|

| Tour group at Cirque du Soleil. |

Cirque du Soleil is a Montreal, Quebec-based company recognized worldwide for high-quality, artistic entertainment. Since its founding in 1984, Cirque du Soleil has sought to evoke the imagination, invoke the senses and provoke the emotions of people around the world. Here are some fun facts about the company:

- In 1984, 73 people worked for Cirque du Soleil. Today, the business has 5,000 employees worldwide, including more than 1,300 artists. The Montreal International Headquarters alone has nearly 2,000 employees.

- There are eight Cirque shows in Las Vegas, NV, and one in Florida. The U.S-based permanent shows have a safety manager. For the traveling show, safety is handled by staff in Montreal. They work to share best practices.

- More than 100 occupations can be found at Cirque.

- The company’s employees and artists represent more than 50 nationalities and speak 25 different languages. Employees at the La Nouba location in Florida speak 14 languages.

- More than 100 million spectators have seen a Cirque du Soleil show since 1984. Close to 15 million people saw a Cirque du Soleil show in 2013.

|

| Rob Pooley explains a safety improvement on a prop up on the grid. |

During ASSE's Safety 2014, a group of attendees took a backstage technical tour of Cirque du Soleil La Nouba at Downtown Disney. I selected this tour because I participated in the Cirque Love technical tour last year, and I was fascinated. Also, I work for Walt Disney World, and although I have seen La Nouba, I have never had the chance to take a technical tour. The tour was as fascinating as the final product (the show).

Our group was divided into three smaller groups for safety and for ease of communication. My group was paired with Rob Pooley, head of automation. He has been in the business all of his life, came from Europe to join Cirque 16 years ago, and spoke with a thick Scottish accent.

Cirque performers typically come from a long lineage of circus families, or are world-renowned Olympic gymnasts. Some current performers are the 7th generation of performers in their families. This type of performing is in their blood. Even in light of these lifelong affiliations, Cirque provides training on CPR, emergency response, bloodborne pathogens, fall protection, rope access, and provides OSHA 10-hour course to all performers. Additionally, emergency medical technicians are always present on set, in costume during performances. You wouldn’t know them unless you knew what you were looking for. I’ve seen La Nouba and I had no idea the folks dressed in white chicken costumes were performing the duties of EMTs. Impressive.

Our group was divided into three smaller groups for safety and for ease of communication. My group was paired with Rob Pooley, head of automation. He has been in the business all of his life, came from Europe to join Cirque 16 years ago, and spoke with a thick Scottish accent.

Cirque performers typically come from a long lineage of circus families, or are world-renowned Olympic gymnasts. Some current performers are the 7th generation of performers in their families. This type of performing is in their blood. Even in light of these lifelong affiliations, Cirque provides training on CPR, emergency response, bloodborne pathogens, fall protection, rope access, and provides OSHA 10-hour course to all performers. Additionally, emergency medical technicians are always present on set, in costume during performances. You wouldn’t know them unless you knew what you were looking for. I’ve seen La Nouba and I had no idea the folks dressed in white chicken costumes were performing the duties of EMTs. Impressive.

The safety culture was apparent. Each day begins at 8 a.m. with inspections. At noon, 4-hour rehearsals begin. This location has an elaborate training room with free weights, nautilus equipment, trapeze equipment, various props, a ballet barre, trampolines, bike ramps and a host of other areas for the performers to perfect the show. Not only was the backstage area immaculate, I repeatedly heard sentiments such as: “Everyone takes safety into their own hands, they are responsible for their own safety as well as everyone else’s.”

Rob took great pride in sharing some of the safety improvements that have been made over the past 16 years. Here are just a few:

Rob took great pride in sharing some of the safety improvements that have been made over the past 16 years. Here are just a few:

- Moving reset buttons to the front of the PLC panels for the winches (used to fly performers) so they don’t need to open the cabinets to reset them.

- Improving the ability for performers to climb into their prop, then be lowered from the grid (which is a permeable working surface present at the top of many fly lofts that is used to support and provide access to many of a rigging system's components) instead of having to climb down a ladder from the grid to their props.

- Replacing lighting units with lights that are accessible from a fixed area so maintenance can be completed on solid ground instead of while hanging.

- Adding innumerable ladders and sets of stairs to provide easy access to the hundreds of platforms on the multitiered stage.

- The installation of rescue ladders so a rescuer and a gurney to be transported easily to an injured performer or one needing rescue from a suspended state.

|

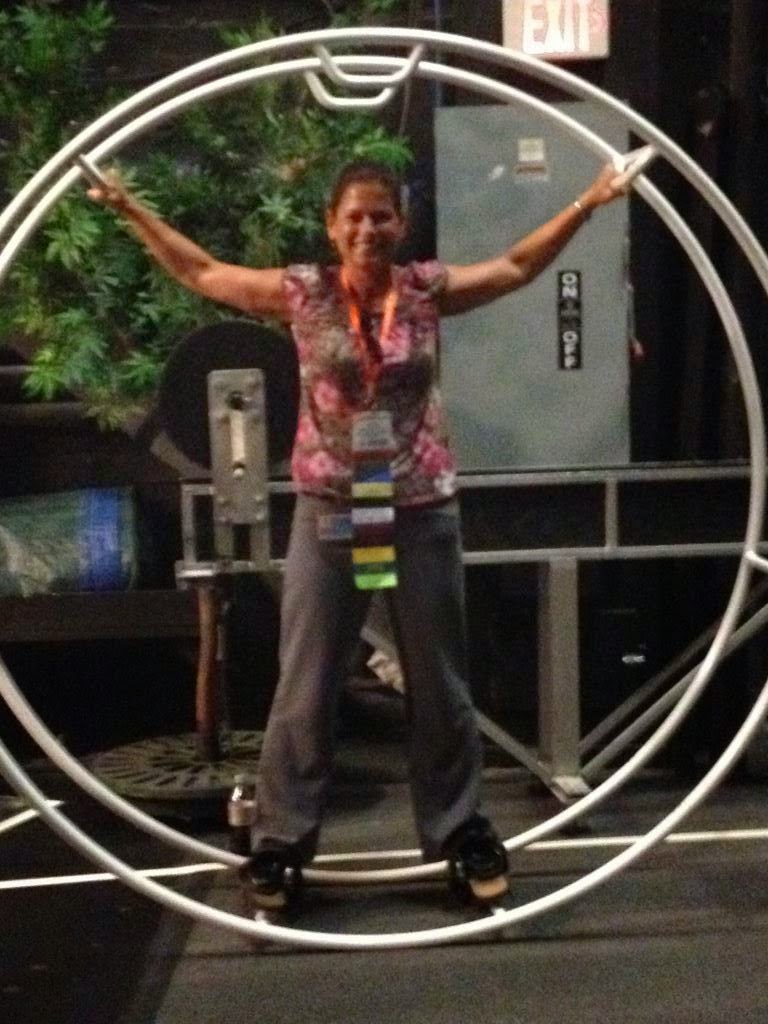

| Heather tests out the German Wheel (I couldn't spin it for safety reasons). |

It was a fantastic, informative, educational tour. We are very appreciative of ASSE for hosting technical tours at the annual PDC, as well as the host location companies that volunteer their staff’s time to share knowledge and further the education of attendees.

A quote from Rob sums up how important everyone’s role is at La Nouba: “Sometimes we are asked, 'Do you get bored doing the same thing over and over again?' Every time you push a button around here someone could be injured or killed. If you are bored, you need to go work someplace else.”

A quote from Rob sums up how important everyone’s role is at La Nouba: “Sometimes we are asked, 'Do you get bored doing the same thing over and over again?' Every time you push a button around here someone could be injured or killed. If you are bored, you need to go work someplace else.”

Live From Safety 2014: Safety Is a Noble Profession

Post by Safety 2014 Guest Blogger Patrick Karol, CSP, ARM

During the Tuesday general session at ASSE's Safety 2014, the Society recognized several safety professionals for their contributions to the field today, But it was Gary Barnett’s comments that caught my attention and gave me pause to think. Gary, who is from ASSE's New Jersey Chapter, was honored as a Society Fellow, which recognizes a lifetime of achievement and is the highest honor in the profession. He called the safety profession a “noble” profession and encouraged attendees to share their knowledge.

During the Tuesday general session at ASSE's Safety 2014, the Society recognized several safety professionals for their contributions to the field today, But it was Gary Barnett’s comments that caught my attention and gave me pause to think. Gary, who is from ASSE's New Jersey Chapter, was honored as a Society Fellow, which recognizes a lifetime of achievement and is the highest honor in the profession. He called the safety profession a “noble” profession and encouraged attendees to share their knowledge.

Ensuring that our employees do not get hurt, so they can go home to family and friends is a noble cause. It’s the moral driver and why we do what we do, but it’s also easy to forget. After all, we have inspections and audits to conduct, checklists to complete, regulations to interpret and employees to train. In addition, expectations of the safety professional continue to grow. We are beginning to integrate into the business which means we need to better communicators by tailoring our messages to our audience. We need to define safety in financial terms when we speak with the CFO, in efficiency terms when we speak to operations, in legal terms when we speak to the lawyers and so forth. We need to be a strategist and stay abreast of the latest developments in the safety world. Becoming a business partner rather than simply a stand-alone component means more will be expected of us.

With so much going on, it’s easy to understand how we can forget that our profession is a noble one. It’s noble because we take satisfaction when our employees return home to their family and friends the way they came to work. It’s noble because we truly show how much we care by ensuring that hazards that cause injury are identified and corrected. It’s noble because there is no better way to show you care than to create a workplace where people can work without fear of being injured.

Yes, the safety profession is a noble profession. Thanks to Gary Barnett, ASSE Fellow, for reminding me.

Patrick J. Karol, CSP, ARM, is manager, safety and risk control with Aramark in Philadelphia, PA.

Patrick J. Karol, CSP, ARM, is manager, safety and risk control with Aramark in Philadelphia, PA.

Live From Safety 2014: Reducing Frequency & Severity of Human Error

Post by Safety 2014 Guest Blogger Frank D'Orsi, CSP, ARM

Human error is often identified as a cause for workplace incidents and injuries. In his Safety 2014 concurrent education session, Tom Harvey delivered a high-energy presentation that highlighted the failures of establishing causation by focusing on symptoms of the system (e.g., incidents, mistakes, violations, injuries, near hits, property damage). Instead, Tom explained, the focus should be on situational error traps, drift error traps, leadership, culture, job design, ineffective tool use, system breakdown and organizational weaknesses. Situational traps are defined as time pressure, distraction or interruption, multitasking, over confidence, vague guidance, first shift/last shift characteristics, peer pressure, job scope change, physical environment and mental fatigue.

Human error is often identified as a cause for workplace incidents and injuries. In his Safety 2014 concurrent education session, Tom Harvey delivered a high-energy presentation that highlighted the failures of establishing causation by focusing on symptoms of the system (e.g., incidents, mistakes, violations, injuries, near hits, property damage). Instead, Tom explained, the focus should be on situational error traps, drift error traps, leadership, culture, job design, ineffective tool use, system breakdown and organizational weaknesses. Situational traps are defined as time pressure, distraction or interruption, multitasking, over confidence, vague guidance, first shift/last shift characteristics, peer pressure, job scope change, physical environment and mental fatigue.

Normal drift traps that creep in over time include temperature change, shortcuts, extending tool and machinery preventive maintenance, conflicting values, bad habits and vague policies, ineffective training, flawed procedures, faulty equipment, faulty technology, design and engineering, and lack of accountability. These situational and error drifts get larger over time if not addressed, and this can result in a higher frequency of mishaps with greater severity.

Tom highlighted several tools that can be used to correct the causes of increased frequency and severity:

- Question attitudes, confidence and complacency.

- Conduct job plan analysis.

- Plan tasks from 5 to 30 minutes and conduct pretask briefs.

- Self-check before and while working.

- Develop effective communication.

- Use procedures.

- Perform place keeping. Don't allow interruptions to cause you to forget where you are in the task steps.

- Peer check. Watch out for co-workers.

- Perform coaching with constructive feedback.

- Conduct after-task reviews.

Tuesday, June 10, 2014

Live From Safety 2014: Keep the Discussion About Risk Alive

Dr. Sidney Dekker took to the stage today at ASSE's Safety 2014. During his keynote address, he shared his belief that success is the enemy of safety and that the current obsession with zero is an "erosion of safety." Dekker sees a big difference between the commitment to zero and efforts to make it a goal to achieve statistically--or what Dekker called the LGI--the looking good indicator.

According to Dekker, to take the next step in safety performance, OSH professionals need to let go of the ideas that have brought safety to this point in its history. "The more we seem to do the less we seem to yield," he explained. "Those ideas are keeping us here, but won't lead to something fundamentally different."

Dekker also implored attendees to recognize one key truth: "One best method only works in a world that doesn't change, that has no variables." In the real world, workers often have to finish designs to get the job done safely. These workarounds aren't ever captured as incidents because they are perceived as normal. That's why, when things go wrong, the first thought shouldn't be figuring out who to blame but rather why did it make sense for that worker to do what he did in that circumstance.

"Murphy was wrong," Dekker said. "Everything that can go wrong usually goes right, and then we draw the wrong conclusion. . . . The enemy of safety is success."

Dekker also implored attendees to recognize one key truth: "One best method only works in a world that doesn't change, that has no variables." In the real world, workers often have to finish designs to get the job done safely. These workarounds aren't ever captured as incidents because they are perceived as normal. That's why, when things go wrong, the first thought shouldn't be figuring out who to blame but rather why did it make sense for that worker to do what he did in that circumstance.

"Murphy was wrong," Dekker said. "Everything that can go wrong usually goes right, and then we draw the wrong conclusion. . . . The enemy of safety is success."

So how can OSH professionals keep the discussion about risk alive?

- Discuss threats before work proceeds.

- Bring in fresh viewpoints.

- Have the capacity to say no.

Before concluding, Dekker advised attendees not to think about leading workers to safety every day: "Lead workers into risk every day and make them risk competent not risk averse. You can set expectations or you can create possibilities."

Live From Safety 2014: Are You Delivering High-Impact Learning?

Training is one of those topics OSH professionals address almost daily. What training is needed? How do I engage trainees? How do I know whether the training is improving safety in the workplace?

Chris Ross addressed these topics and more during his Safety 2014 concurrent session, "High-Impact Learning: Using a New Model to Achieve Results." In the session sponsored by ASSE centennial sponor ClickSafety, Ross offered fresh insight into the topic of performance management, which he sees as a great opportunity for OSH professionals to build relationships and partnerships with senior management."

"Knowledge needs to be used to achieve a specific business result," Ross explained. "But there is a gap between what we are doing and what we should be doing." According to Ross, research suggests that 85% to 98% of training value is wasted because people get trained but they aren't able to apply the training in a way that improves performance to help achieve business goals.

Traditional training paradigms, such as those based on Bloom's taxonomy and Kirkpatrick's levels of training, can lead to effective learning, but gaps still exist, often because these questions are not asked or answered:

"Knowledge needs to be used to achieve a specific business result," Ross explained. "But there is a gap between what we are doing and what we should be doing." According to Ross, research suggests that 85% to 98% of training value is wasted because people get trained but they aren't able to apply the training in a way that improves performance to help achieve business goals.

Traditional training paradigms, such as those based on Bloom's taxonomy and Kirkpatrick's levels of training, can lead to effective learning, but gaps still exist, often because these questions are not asked or answered:

- What will the person be able to do as a result of this training?

- What will the performer know as a result of this training?

Both must be asked and answered in order to change some of the levers that get organizational results, Ross said.

Companies must also strive to create a process the drives performance. "It's important to define business outcomes in addition to learning outcomes," he said, noting that this disconnect often prevents training from having the intended outcome--namely improved performance.

When it comes to developing training that will deliver high impact, a key step is developing an impact map that clearly links the training to a business goal. Then, you need to educate and motivate managers and learners to facilitate a dialogue about that impact map between managers and learner. Then, you have to prepare the facilitator to leverage the impact map during the program.

Ross also noted that much effort is focused on developing the training itself (primarily a PowerPoint), but not enough attention is given to providing the support and reinforcement workers need after training to ensure that the new skills and knowledge are applied effectively in the workplace. "After learning, you have to help managers address learning obstacles that may be preventing the training from being applied on the job."

He also recommended that OSH professionals employ the success case method more readily to show the value of the training being delivered. Here are the steps he recommends:

"Getting best at communicating value is a huge win," Ross explained, particularly when resources are scarce. It's also a great way to start moving your interactions with senior management from transactional to transformational and changing their perception of you from adversary to responder to enabler. To make that key point, Ross shared this quote, from Jac Fitz-enz: "Senior managers do not accept activities in place of value."

To go about that, Ross offered these tips: "Change participants' expectation from learn to using. And change manager expectations from sending employees to learn to supporting the application of their learning after training."

Companies must also strive to create a process the drives performance. "It's important to define business outcomes in addition to learning outcomes," he said, noting that this disconnect often prevents training from having the intended outcome--namely improved performance.

When it comes to developing training that will deliver high impact, a key step is developing an impact map that clearly links the training to a business goal. Then, you need to educate and motivate managers and learners to facilitate a dialogue about that impact map between managers and learner. Then, you have to prepare the facilitator to leverage the impact map during the program.

He also recommended that OSH professionals employ the success case method more readily to show the value of the training being delivered. Here are the steps he recommends:

- Use results to estimate value created and left one the table.

- Tell a compelling story. Survey participants, analyze the scope of impact and conduct interviews to capture this information.

- Celebrate role of manager in success.

- Improve subsequent offerings.

- Capture unrealized revenue.

"Getting best at communicating value is a huge win," Ross explained, particularly when resources are scarce. It's also a great way to start moving your interactions with senior management from transactional to transformational and changing their perception of you from adversary to responder to enabler. To make that key point, Ross shared this quote, from Jac Fitz-enz: "Senior managers do not accept activities in place of value."

To go about that, Ross offered these tips: "Change participants' expectation from learn to using. And change manager expectations from sending employees to learn to supporting the application of their learning after training."

Live From Safety 2014: How Do You Define These 12 Key Words?

During his concurrent education session at ASSE's Safety 2014 in Orlando, FL, James "Skipper" Kendrick discussed 12 key words in the OSH profession:

- compliance

- business

- people

- personal

- system

- leadership

- management

- risks

- error

- design

- metrics

- results

He prefaced his discussion with a couple of caveats: None of these words are unfamiliar to OSH professionals and all of them are topics in the Safety 2014 program, much like many of them have been talked about a previous conferences, seminars and workshops. And, that, Kendrick said, is why they remain important. "If we are talking these 12 words, how well are we walking them in our workplaces?"

Kendrick then asked attendees to be brutally honest as in assessing the current state of their own programs--on a scale of 5 (excellent), 3 (good) and 1 (lacking) as he progressed through a discussion of each word. Here are some highlights:

- Compliance: It's a given--the baseline.

- Business: You have to understand how you contribute to your organization's business.

- People: Everything you do as an OSH professional is about people.

- System: A system is continual and ever improving--and you have to keep a focus on that.

- Leadership: It's not just those who are known leaders, but also the silent leaders you can count on to advocate for safety.

- Management: What gets managed gets done.

- Risks: Nothing is risk free. It's one thing to define the hazards of the work, but you also have to identify, understand and control the associated risks.

- Errors: Remember that errors are not the same as violations. Organizations should welcome reports and feedback on error in order to reduce or eliminate consequences.

- Design: Examine the design considerations in everything you do.

- Metrics: Measure the positive things we do instead of focusing solely the problems that arise related to what we intended to do.

- Results: Each organization must define what results are most important.

How does your safety system rate?

Live From Safety 2014: Sprains & Strains = Public Enemy #1

Post by Safety 2014 Guest Blogger Patrick Karol

Sprains and strains are public enemy #1 in most work environments. They are also a tough nut to crack especially when you consider that the same risk factors that lead to occupational injuries also exist off-the-job. It takes education, training and team work to effect change.

Sprains and strains are public enemy #1 in most work environments. They are also a tough nut to crack especially when you consider that the same risk factors that lead to occupational injuries also exist off-the-job. It takes education, training and team work to effect change.

The Disney team and Safety in Motion delivered a great presentation at ASSE's Safety 2014 in Orlando, FL, on how they are cracking that nut. The panel identified three common causal factors including:

- high force;

- awkward posture;

- extreme fatigue that drives injury exposure.

The panel shared animated training that demonstrates the effects of these causal factors and the use of a common language to communicate key ergonomic principles with their “cast members" (folks most of us call employees). Terminology such as green zone, yellow zone and red zone to indicate levels of risk related to body posture increases the likelihood that trainees will understand important training techniques. The presenters also shared the performance alignment model they use to implement their ergonomics program.

- Identify what behavior we want.

- Document source content such as ANSI, ASTM and ASME.

- Develop training, guides and other tools.

- Conduct assessments to ensure compliance with the desired behavior.

- Reinforce key training techniques through accountability and refresher training.

Ergonomics can be a highly technical and complicated field, but Disney’s structured approach, easy-to-understand yet focused training and staff ergonomics expertise to identify engineering controls is a recipe for cracking that nut.

If sprains and strains are your Public Enemy #1, I'd love to hear what you are doing to crack the nut.

Patrick J. Karol, CSP, ARM, is manager, safety and risk control with Aramark in Philadelphia, PA.

If sprains and strains are your Public Enemy #1, I'd love to hear what you are doing to crack the nut.

Patrick J. Karol, CSP, ARM, is manager, safety and risk control with Aramark in Philadelphia, PA.

Live From Safety 2014: Creating a "Deep Safe" Organization

Corrie Pitzer, a well-known consultant in strategic safety management, delivered an entertaining and engaging session, "Deep Safe: The Future of Safety (Engineering)," at ASSE's Safety 2014 in Orlando, FL. With a distinctive flair and charming wit, Pitzer shared a slightly different view of safety based on his experience working in high-hazard industries, such a mines in South Africa. "People are paralyzed by protection," Pitzer explained. "Human performance follows an 's' curve. When you reach compliance level, performance tapers off."

In many ways, Pitzer said, we have become so protected that we often don't even look anymore--we simply don't perceive the risk. He termed this the Titanic curve, "As we see an increase in protection, we see an increase in failure." People start pretending that things are safe, so much so that they start believing it. This, Pitzer called "paralysis by pretension," adding that we are "losing the clarity we need to truly analyze what is going on."

Pitzer also contended that too many incident investigations hone in on the negative attributes of human nature when instead employers should find ways to capitalize on human's best qualities--such as our ability to sense, be intuitive, imagine, perceive, innovate, sacrifice and inspire. And most of all, to be passionate. "You each have employees who can be awesome if you let them." This, he said, is the key to becoming a "Deep Safe" organization.

Pitzer also pointed to five characteristics of the U.S. Marine Corps as something companies should embrace in their efforts to create awesome employees and become Deep Safe companies:

In many ways, Pitzer said, we have become so protected that we often don't even look anymore--we simply don't perceive the risk. He termed this the Titanic curve, "As we see an increase in protection, we see an increase in failure." People start pretending that things are safe, so much so that they start believing it. This, Pitzer called "paralysis by pretension," adding that we are "losing the clarity we need to truly analyze what is going on."

Pitzer also contended that too many incident investigations hone in on the negative attributes of human nature when instead employers should find ways to capitalize on human's best qualities--such as our ability to sense, be intuitive, imagine, perceive, innovate, sacrifice and inspire. And most of all, to be passionate. "You each have employees who can be awesome if you let them." This, he said, is the key to becoming a "Deep Safe" organization.

Pitzer also pointed to five characteristics of the U.S. Marine Corps as something companies should embrace in their efforts to create awesome employees and become Deep Safe companies:

- Attention to detail.

- Strict discipline.

- Obsessive loyalty.

- Systematically observant.

- Potency in risk.

What's also important, Pitzer concluded, is training workers how to recognize and deal with risk. This will help safety become "invisible" because it's ultimately not about books or manuals or checklists, but about what is inside of each of them.

Monday, June 9, 2014

Live From Safety 2014: Legal Implications of Voluntary Consensus Standards

Post by Safety 2014 Guest Blogger Frank D'Orsi, CSP, ARM

As Adele explains it, when MSHA and OSHA were first formed they had few standards and regulations to work with and as such adopted many consensus standards through reference into their regulations. When adopting consensus standards by reference into the regulations, the compliance agencies must go through a public notice and comment period.

In many current MSHA and OSHA regulations, which date back to the 1960s and 1970s, the referenced standards are a better measure of safety program guidelines for development. However, the consensus standards referenced may not be the most current version. So, it's best if safety professionals check that they are using the most current version of referenced consensus standards because even if they're not referenced in the regulations they may carry greater weight and liability potential if not adopted and used. Adele also explained the various legal implications the employer may have with respect to consensus standards and compliance.

The detailed proceedings document for this presentation should be a must-read for all safety professionals for not only the history and parameters established for the public consensus committees and standards development, but also the adoption into the compliance regulations and the potential employer liability that they create.

Live From Safety 2014: Charles Duhigg & The Power of Habit

Post by Safety 2014 Guest Blogger Patrick Karol

It’s the $10,000 question in safety and health: “How do you get employees to follow safety rules and procedures?” My conventional wisdom tells me to document procedures, train to the procedures and enforce the procedures.

Well, this morning at ASSE's Safety 2014, Charles Duhigg certainly challenged my conventional wisdom on habit strengths. Building a habit without the right rewards leads to the equivalent of sleep walking at work. It starts with identifying keystone habits or what others might call triggers. Those habits are powerful levers that spill over to other habits. But, identifying keystone habits is not always easy as Duhigg explained with an example about the marketing of Febreze. I have often viewed the use of PPE as a trigger habit. It’s a daily and visible sign that indicates a basic understanding of potential hazards, and maybe even a willingness to accept new safety-related habits.

The reward is another key component of building strong habits that are often misunderstand or misused. Pizza lunches are a nice way to say thanks, but fall short of emotion and ultimately don't change or sustain a habit. Yet, we buy lots of pizzas with that intent in mind. The most effective rewards, Duhigg says, are rewards that contain or connect to our emotions. I don’t exactly get emotional when I eat pizza, although I am appreciative if someone else is buying. Identifying emotionally connected rewards isn’t easy either. Money, while nice, doesn’t work. Once it’s spent, it loses any connection to the habit that prompted the reward.

Since our personal and organizational habits are closely tied to our culture, how we change or establish habits falls somewhere close to the holy grail of safety. The right keystone habits coupled with rewards that contain or connect to emotions builds sustainable habit strength. So, I'm interested to know:

Well, this morning at ASSE's Safety 2014, Charles Duhigg certainly challenged my conventional wisdom on habit strengths. Building a habit without the right rewards leads to the equivalent of sleep walking at work. It starts with identifying keystone habits or what others might call triggers. Those habits are powerful levers that spill over to other habits. But, identifying keystone habits is not always easy as Duhigg explained with an example about the marketing of Febreze. I have often viewed the use of PPE as a trigger habit. It’s a daily and visible sign that indicates a basic understanding of potential hazards, and maybe even a willingness to accept new safety-related habits.

The reward is another key component of building strong habits that are often misunderstand or misused. Pizza lunches are a nice way to say thanks, but fall short of emotion and ultimately don't change or sustain a habit. Yet, we buy lots of pizzas with that intent in mind. The most effective rewards, Duhigg says, are rewards that contain or connect to our emotions. I don’t exactly get emotional when I eat pizza, although I am appreciative if someone else is buying. Identifying emotionally connected rewards isn’t easy either. Money, while nice, doesn’t work. Once it’s spent, it loses any connection to the habit that prompted the reward.

Since our personal and organizational habits are closely tied to our culture, how we change or establish habits falls somewhere close to the holy grail of safety. The right keystone habits coupled with rewards that contain or connect to emotions builds sustainable habit strength. So, I'm interested to know:

- What type of behaviors do you consider to be keystone habits in your operation?

- What are your most effective rewards that contain emotion?

Patrick J. Karol, CSP, ARM, is manager, safety and risk control with Aramark in Philadelphia, PA.

Live From Safety 2014: The Most Powerful Habits Involve Emotion--Tap Into It

Safety 2014 keynote speaker Charles Duhigg, author of the New York Times best-seller The Power of Habit, engaged the audience with his insights on how much of human behavior is habit and how OSH professionals can harness that knowledge to ignite culture change. Citing research on neurological activities, Duhigg noted that 40% to 45% of our behaviors are habit rather than decisions. The most important among those habits are known as keystone habits.

Why are they so powerful? Duhigg explains that keystone habits (for example, exercising every day) can "set of a chain of events that can change other habits as well." The process of identifying these habits is to understand the cues that trigger the routing and lead to some desired reward. To do this, Duhigg said, you have to figure out what reward will create the habit. In other words, "You have to make sure the reward is actually rewarding to encourage the behavior that you want to become automatic." Said another way, "The most powerful rewards deliver emotional payoff" and that's what helps employees envision the habits you are rewarding as the culture.

Duhigg shared the example of Paul O'Neill and Alcoa. Upon taking over as CEO of Alcoa, O'Neill got on stage and announced that he was going to talk about safety. Instead of discussing profits and other business buzzwords, O'Neill stated his intention to make Alcoa the safest company in the world. In other words, safety was the keystone habit O'Neill decided to change across the corporation. "If you want to understand how Alcoa is doing, you need to look at our workplace safety figures," O'Neill said. The results were telling--Alcoa's profits soared. "It spilled into a habit of excellence," Duhigg explained.

Duhigg also shared how Starbucks learned from a public relations debacle involving poor customer service to teach its employees better habits--including making will power a habit. "Will power is the single greatest correlate to future success," he said.

In the end, it's about values, Duhigg said. "Keystone habits are a new way of talking to each other about our values. Our habits reflect our values."

Why are they so powerful? Duhigg explains that keystone habits (for example, exercising every day) can "set of a chain of events that can change other habits as well." The process of identifying these habits is to understand the cues that trigger the routing and lead to some desired reward. To do this, Duhigg said, you have to figure out what reward will create the habit. In other words, "You have to make sure the reward is actually rewarding to encourage the behavior that you want to become automatic." Said another way, "The most powerful rewards deliver emotional payoff" and that's what helps employees envision the habits you are rewarding as the culture.

Duhigg shared the example of Paul O'Neill and Alcoa. Upon taking over as CEO of Alcoa, O'Neill got on stage and announced that he was going to talk about safety. Instead of discussing profits and other business buzzwords, O'Neill stated his intention to make Alcoa the safest company in the world. In other words, safety was the keystone habit O'Neill decided to change across the corporation. "If you want to understand how Alcoa is doing, you need to look at our workplace safety figures," O'Neill said. The results were telling--Alcoa's profits soared. "It spilled into a habit of excellence," Duhigg explained.

Duhigg also shared how Starbucks learned from a public relations debacle involving poor customer service to teach its employees better habits--including making will power a habit. "Will power is the single greatest correlate to future success," he said.

In the end, it's about values, Duhigg said. "Keystone habits are a new way of talking to each other about our values. Our habits reflect our values."

Live From Safety 2014: How Do You Spell Change?

Post From Safety 2014 Guest Blogger Pam Walaski, CSP, CHMM

I spell it A-S-S-E. At Sunday’s House of Delegates (HOD) meeting at Safety 2014, the delegates from chapters and practice specialties voted overwhelmingly to change the Society’s governance structure; the vote was 166 in favor and 31 opposed. This change is the first since 1995 and is the culmination of former Society President Darryl Hill’s idea that started a 3+ year process of collaboration and discussion.

I took the opportunity to speak before my fellow delegates and voiced my belief that the model we were asked to vote on represented the one that was best for the majority of the more than 36,000 members. It was not the model that I would have designed if it were up to me alone. But it wasn’t my model because it’s not my Society. It’s a Society that I share with many of the world’s best professionals in the field, all of whom have different ideas about how ASSE should function and all of whom have a different set of desires, needs and wants from the Society. And we all have something to offer in the discussions.

It was a model that was created in a collaborative process involving all facets of the Society, reviewed and modified numerous times by Society groups and finally presented for discussion and vote to all of the members through the HOD. As a result it is a model that, as they say, “has something for everyone” and provides for the best chance for ASSE to continue to grow and flourish.

It is also important to restate something ASSE President Kathy Seabrook said during the HOD meeting – this governance change isn’t coming because ASSE is broken or losing its global relevance. This isn't a desperate long-shot to save ASSE. We are growing, both in terms of the number of members and the influence we have on OSH trends. This model will provide the platform we need to continue this process and our progress.

And now as they say, the devil is in the details. Several implementation tasks have yet to be completely decided. But they couldn’t be at this stage of the game. The HOD approved the model that now will be operationalized. ASSE's board will now begin to put in place the mechanism and activities that will take ASSE from a 15-member board that sometimes requires lengthy periods of time and discussion to decisions to a 10-member nimble board that will focus on strategy, moving more operational decision to the region and chapter levels.

I’m happy with this change. I’ve believed in it since the beginning, and I hope all fellow members who were not in support will eventually come to believe the same.

Pam Walaski, CSP, CHMM, is the regional manager, Environmental, Health and Safety Services, for Compliance Management International in Pittsburgh, PA. She is Administrator of ASSE's Consultants Practice Specialty and a member of the Western Pennsylvania Chapter.

I spell it A-S-S-E. At Sunday’s House of Delegates (HOD) meeting at Safety 2014, the delegates from chapters and practice specialties voted overwhelmingly to change the Society’s governance structure; the vote was 166 in favor and 31 opposed. This change is the first since 1995 and is the culmination of former Society President Darryl Hill’s idea that started a 3+ year process of collaboration and discussion.

I took the opportunity to speak before my fellow delegates and voiced my belief that the model we were asked to vote on represented the one that was best for the majority of the more than 36,000 members. It was not the model that I would have designed if it were up to me alone. But it wasn’t my model because it’s not my Society. It’s a Society that I share with many of the world’s best professionals in the field, all of whom have different ideas about how ASSE should function and all of whom have a different set of desires, needs and wants from the Society. And we all have something to offer in the discussions.

It was a model that was created in a collaborative process involving all facets of the Society, reviewed and modified numerous times by Society groups and finally presented for discussion and vote to all of the members through the HOD. As a result it is a model that, as they say, “has something for everyone” and provides for the best chance for ASSE to continue to grow and flourish.

It is also important to restate something ASSE President Kathy Seabrook said during the HOD meeting – this governance change isn’t coming because ASSE is broken or losing its global relevance. This isn't a desperate long-shot to save ASSE. We are growing, both in terms of the number of members and the influence we have on OSH trends. This model will provide the platform we need to continue this process and our progress.

And now as they say, the devil is in the details. Several implementation tasks have yet to be completely decided. But they couldn’t be at this stage of the game. The HOD approved the model that now will be operationalized. ASSE's board will now begin to put in place the mechanism and activities that will take ASSE from a 15-member board that sometimes requires lengthy periods of time and discussion to decisions to a 10-member nimble board that will focus on strategy, moving more operational decision to the region and chapter levels.

I’m happy with this change. I’ve believed in it since the beginning, and I hope all fellow members who were not in support will eventually come to believe the same.

Pam Walaski, CSP, CHMM, is the regional manager, Environmental, Health and Safety Services, for Compliance Management International in Pittsburgh, PA. She is Administrator of ASSE's Consultants Practice Specialty and a member of the Western Pennsylvania Chapter.

Live From Safety 2014: Human Error & Safety

Post by Safety 2014 Guest Blogger Steve Minshall, CSP, CIH

Who Has My Socks?

“So just who is it that’s replacing Todd Conklin?” I

remarked to my newfound colleague, Barb Semeniuk (it means “Smith” in

Ukrainian, I was informed), from Edmonton, Alberta, as I settled into my seat

in the Human Error and Safety pre conference seminar at ASSE's Safety2014. Barb pointed to the bio sitting in front

of me and then to Bob Edwards who was then standing at the front of the room. “He’s

the guy,” she said with no hint of appraisal.

I wasn’t sure who to expect since I hadn’t paid close attention when I received a phone call from ASSE telling me that Todd Conklin, the originally scheduled speaker for the seminar, was not available and that someone unknown to me was taking his place. Did I want to stick with this seminar, the caller intoned? “Yes, yes,” I replied though not because of any recognition of the new speaker‘s name or credentials but because the topic still interested me even if the speaker didn’t.

I wasn’t sure who to expect since I hadn’t paid close attention when I received a phone call from ASSE telling me that Todd Conklin, the originally scheduled speaker for the seminar, was not available and that someone unknown to me was taking his place. Did I want to stick with this seminar, the caller intoned? “Yes, yes,” I replied though not because of any recognition of the new speaker‘s name or credentials but because the topic still interested me even if the speaker didn’t.

OK, so I came to the seminar in a bit of a blasé funk

because I was disappointed not to get to see and hear the renowned safety

thought-leader and speaker, Todd Conklin. I should not have worried. In my

vernacular, Bob Edwards knocked my socks off not only with the information he

presented but also with his engaging presentation style.

Just who is Bob Edwards? He is the human and organizational performance advocate for General Electric – now tell me, who else do you know that has a cool title like that? Bob has a military bearing, as well he should, having spent 6 years in the Army; he stands more than 6 ft tall, and looks the part of a serious person. He’s 52 but looks like he’s in his 30s. But looks can be deceiving and Bob turns out to be one of the nicest and most engaging people I’ve had the pleasure of meeting. (He also has a son in the Marines who just returned from active duty in Afghanistan – many thanks to Bob and his son for their service to our country.)

His degree is in mechanical engineering and his resume includes work in design, mechanical and technical support teams and as a safety leader. And, as it turns out, Bob is not just some hapless recruit brought in to fill in for Todd Conklin (who had to jet off to New Zealand). Bob has worked with Todd and a student of the Conklin philosophy. He may have his own presentation style but he’s clearly an advocate of Dr. Conklin’s work. With apologies to Dr. Conklin for no longer being disappointed that he could not be here to speak, Bob was terrific and he exceeded my expectations for the content and delivery of the material.

We covered many topics but the central messages I heard were these: 1) Blame and punishment will not advance our safety efforts; 2) learning and improving, as mundane as those two words may sound, supplant blame and punishment as the means to safety improvement; 3) compliance enforcement is important but it does not equate to more safety; 4) we can do better incident investigations by starting with the process; 5) how work is accomplished as we imagine it is not the same as how work is accomplished in reality; and 6) we should be less interested in human error and more interested in learning. Let me briefly explain each of these.

- Blame and punishment. I have to admit I’m not big on punishment. And yet I, and perhaps like you, have experienced situations where people have been disciplined or even let go as the result of an accident – and this happened before the investigation was fully underway or the facts fully known; those doing the firing felt justified because they had removed a “problem” from the company. Bob described this phenomenon in the recent horrific sinking of a South Korean ferry, resulting in the deaths of many school-age children. The ferry captain, who by accounts is a good man and had actually been trying to save the ferry, is under arrest for murder. The overriding emotion, though, is that those in charge desperately want to know that the “system” is in balance and if the captain is out of the system, everything will be okay again. What does firing the captain, charging him with murder and arresting the crew truly do to help understand this tragedy? What learning takes place under these conditions? Those in charge may feel morally justified and they may have satisfied an intense need to re-exert control but these actions do nothing to advance learning and the opportunity remains for another ferry to sink.

- Learning and improvement. Perhaps the concept of the value of learning and improvement over blame and punishment is not so new, especially when you think of Stephen Covey’s advice to “seek first to understand and then to be understood.” In the context of this seminar, though, Bob advocates taking an approach that allows those involved in an incident to tell you their story – and there may be multiple stories from several people – because it is the sense we make out of these stories that allows us to learn. Learning ties into understanding which allows us to design better defenses and we then have more success in preventing injuries.

- More compliance does not equal more safety. Compliance is necessary but not sufficient. If you work in a system that has many problems, compliance along with the rules it brings will help make the system safer. As safety improves, though, more rules and more enforcement do not bring along greater safety. “Doing” safety harder and with more intensity does not make for greater safety. If your approach is compliance and enforcement, these words seem heretical. If you work where compliance and enforcement are the norm but you realize that new gains in safety are not coming like they once did, the light may be coming on and you’re nodding in agreement. Keep nodding; you are right.

- Start with the process when conducting incident investigations. A common approach in incident investigations is to start with the event and work backward. Everything seems so linear: this happened which was preceded by this happening and that was preceded by something else and so on. This linear construction can happen because of the availability of 20:20 hindsight – we already know what happened so we can think of it in this straightline fashion. Such an approach disregards how the people doing the job observed things in the moment. The now-known outcome may not have entered their thinking at the time. Therefore, Bob's recommendation is to first find out about the process and understand it from the point of view of the person who actually does the work. Taking time to listen to and understand that narrative is likely to reveal more information than you would ordinarily uncover in the typical hazard hunt method of investigation.

- Work is not the straightforward thing we imagine it to be. Bob illustrated this point by showing us a straight black line that represented the way work is imagined to take place. He then showed us a blue line that represented how work takes place in practice; the blue line was the more tortuous path, full of diversions, interruptions, and other realities of work life. Both lines lead to the same outcome but the blue line represents how things really get done. The black line, if that’s your view of work, is somewhat judgmental and shows a lack of understanding of what it takes to get a job done. Without taking the time to understand the blue line, we cannot learn what we need to know to design better defenses and prevent injuries.

- Be less interested in human error and more interested in learning. My takeaway here was that we need to acknowledge that we humans are imperfect and we will make errors. If we can get past that, we can learn more and consequently design systems that are more error tolerant and resilient. Automotive engineers have learned this lesson; they know people will have crashes (make errors). So now they design and build automobiles with crumple zones, lane drift indicators; crash avoidance systems; early braking systems; and survivability zones built around the use of air bags and seat belts. These design engineers get it and so should we.

It is a bit of a leap of faith to accept that we are

imperfect, that we should acknowledge and embrace that, and that we should

design work systems to be more error tolerant and resilient. This thinking may

startle some and outright displease others who are strongly invested in the way

we’ve been working at safety for a long time. But I find this to be fascinating

stuff, perhaps not yet perfected, but still a move beyond the classic ways of

thinking about safety. It is exciting to be around people who embrace this new

approach and, frankly, today’s session knocked my socks off. If you find

them, please let me know.

Sunday, June 8, 2014

Live From Safety 2014: Incoming ASSE President Trish Ennis Promises Focus on Member Needs